Build Them Right

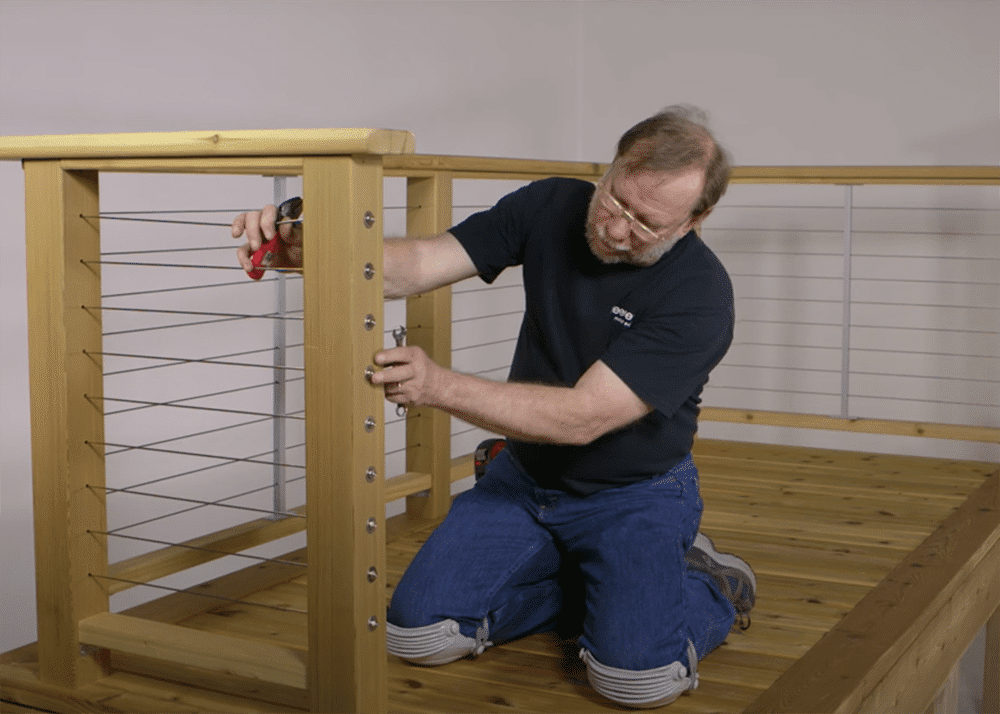

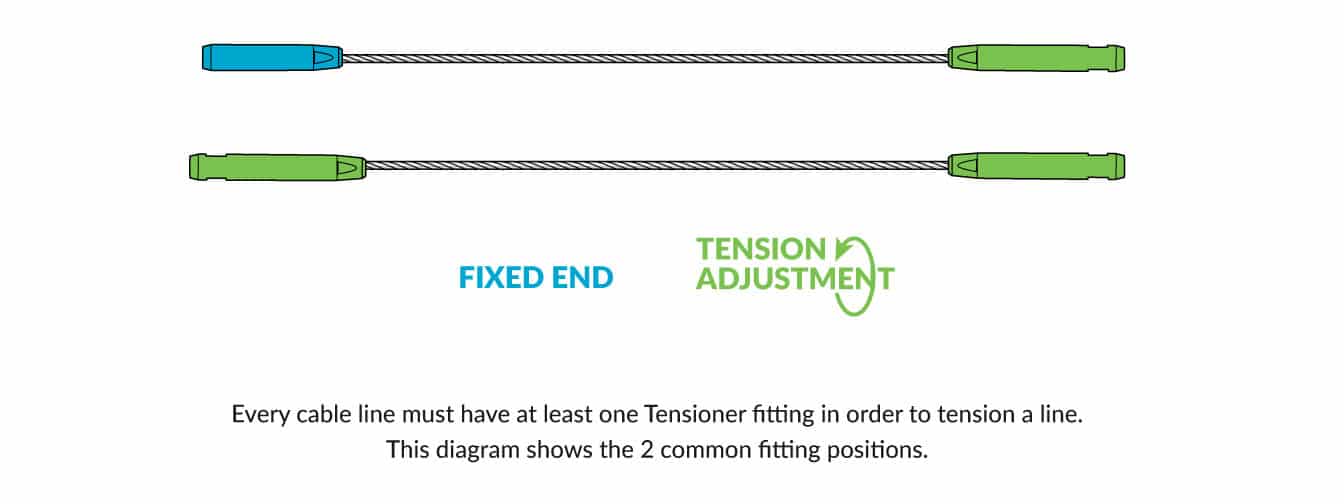

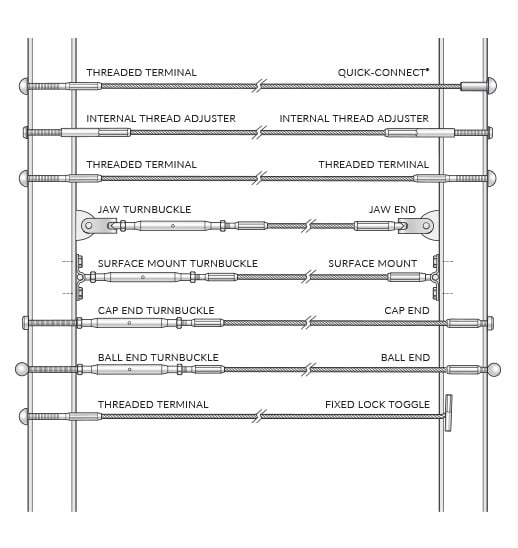

Using our Quick-Connect® style fittings with automatic-locking jaws and our bulk cable you can build your assemblies in the field. The cable end is simply inserted into the fitting and the spring-loaded one-way jaws grab and lock on. If necessary, a reusable release tool can be used to disengage and remove or readjust the fitting. Every cable line must have at least one Tensioner fitting in order to tension a line. This diagram shows the 2 common fitting positions.

Bulk Cable

All fittings and cables are manufactured from high-quality 316-grade stainless steel for weather-tough durability, ultra-low maintenance, and lasting beauty.

Bulk Cable – 1/8″ diameter 1×19 cable construction is available in various lengths for use with CableRail fittings.

Lengths:

| Length | Part # |

| 100-ft | #5100 |

| 250-ft | #5250 |

| 500-ft | #5500 |

Quick-Connect® Jaw

Quick-Connect® fixed end fitting for CableRail, attaches to post face with removable clevis pin.

9901-PKG

Quick-Connect® Jaw Tensioner

Quick-Connect® tension adjustment fitting for CableRail, attaches to post face with removable clevis pin. Special swiveling body to adjust tension.

9912-PKG

Quick-Connect® Jaw Turnbuckle

Quick-Connect® tension adjustment fitting for CableRail, attaches to post face with removable clevis pin.

9900-PKG

Quick-Connect® Surface Mount

Quick-Connect® fixed end fitting for CableRail, attaches to post face using lag screws, bolts, or button head lag screws.

9903W-PKG

Quick-Connect® Surface Mount Turnbuckle

Quick-Connect® tension adjustment fitting for CableRail, attaches to post face using lag screws, bolts, or button head lag screws.

9902W-PKG

Quick-Connect® Surface Mount Tensioner

Quick-Connect® tension adjustment fitting attaches to post face using lag screw bolts, or button head lag screws. Special swiveling body to adjust tension.

9913W-PKG

Quick-Connect® Expansion Anchor Tensioner

Quick-Connect® tension adjustment fitting for anchoring CableRail into masonry wall or posts.

9914-PKG

Quick-Connect® Expansion Anchor

Quick-Connect® fixed end fitting for anchoring CableRail into masonry wall or posts.

9906-PKG

Quick-Connect® Threaded Terminal

Quick-Connect® tension adjustment fitting used to terminate cables when you have access to the outside of the face of the post.

9904-PKG

Quick-Connect® Inset Fitting

Quick-Connect® fixed end fitting for attaching cables through end posts.

3146W-PKG

Quick-Connect® Internal Thread Adjuster

Quick-Connect® tension adjustment fitting, inserts through a drill hole in end post and is secured and adjusted using a bolt and washer (included).

9907-PKG (1-1/2″ Bolt)

9908-PKG (2″ Bolt)

9909-PKG (3″ Bolt)

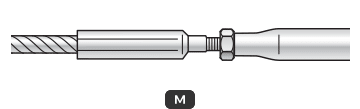

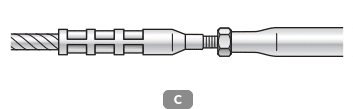

Machine swage fittings are attached to the cable at our factory using a hydraulic cold forming press. The swage shank portion of the fitting is pressed on to the end of the cable and has a uniform hexagonal shape when finished. Assemblies using Machine Swage type fittings are fabricated to you exact lengths in our factory and then shipped ready to install.

CableCrimp style fittings are attached to the cable by hand in the field using a special CambleCrimp Hand Crimper tool. After proper crimping, the fitting will display several evenly spaced compression marks where the tool was engaged. Most 1/8” and 3/16” cable fittings are available in CableCrimp styles.

Fixed Jaw End

Fixed end fitting for CableRail, attaches to post face with removable clevis pin. Machine swaged or hand crimped.

Jaw Turnbuckle

Tension adjustment fitting for CableRail, attaches to post face with removable clevis pin. Machine swaged or hand crimped.

Sleekline Jaw Turnbuckle

Tension adjustment fitting for CableRail, attaches to post face with removable clevis pin. Best suited for CableCrimp swaging. Also available Machine Swaged.

Fixed Surface Mount

Fixed end fitting for CableRail, attaches to post face using lag screws, bolts, or button head lag screws. Machine swaged or hand crimped.

Sleekline Surface Mount Turnbuckle

Tension adjustment fitting for CableRail, attaches to post face using lag screws, bolt or button head lag screws. Best suited for CableCrimp swaging. Also available Machine Swaged.

Surface Mount Turnbuckle

Tension adjustment fitting for CableRail, attaches to post face using lag screws, bolts, or button head lag screws. Machine swaged or hand crimped.

Fixed Lock Toggle

Tension adjustment fitting for CableRail, attaches to post face with removable clevis pin. Best suited for CableCrimp swaging. Also available Machine Swaged.

Internal Thread Adjuster

Inserts through a drill hole in end post and is secured and adjusted using a bolt and washer (included).

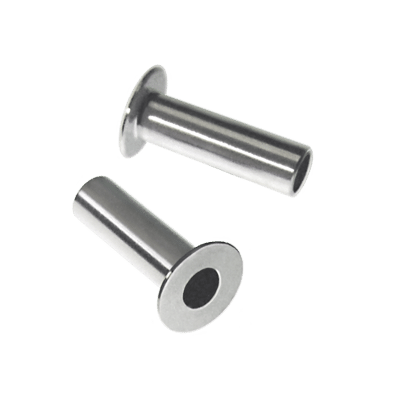

Fixed Ball End

Fixed end fitting, inserted through a drill hole in the end post and secured with a screw-on ball. Machine swaged or hand crimped.

End Ball Turnbuckle

Tension adjustment fitting, through a drill hole in the end post and secured with a screw-on ball. Machine swaged or hand crimped.

Sleekline Ball End Turnbuckle

Tension adjustment fitting, through a drill hole in the end post and secured with a screw-on ball. Best suited for CableCrimp swaging. Also available Machine Swaged.

Fixed Cap End

Fixed end fitting, inserted through a drill hole in the end post and secured with a screw-on end cap. Machine swaged or hand crimped.

Cap End Turnbuckle

Tension adjustment fitting, inserted through a drill hole in the end post and secured with a screw-on end cap. Machine swaged or hand crimped.

Sleekline Cap End Turnbuckle

Tension adjustment fitting, inserted through a drill hole in the end post and secured with a screw-on end cap. Best suited for Cable Crimp swaging. Also available Machine Swaged.

Fixed Button Head

Single piece fitting with non-removable, low profile rounded head. Head rests against the outside face of the post.

Threaded Terminal

CableRail fitting for attachment through post to outside face. Machine swaged or hand crimped.

In-Line Turnbuckle

Used in the middle of a cable assembly for additonal tensioning on long run or where and tensionsing is not feasible or desired.

FAQs

-

Can fittings and cable be purchased separately for fabricating assemblies in the field?

Yes. We offer a wide selection of cables and fittings, many of which include our Quick-Connect® automatic locking-jaw technology, all engineered for easy installation in the field. See our CableRail Fittings page for more information.

-

Can I cut the cables with a pair of wire cutters?

No. Wire cutters will crush the cable and cause you significant frustration during installation. You should use cable cutters that are designed to cleanly shear the cable (see our Cable Cutters #2972-PKG). An electric grinder with a cut-off disk is another option that works very well for trimming both the cable and the excess threads on the Threaded Terminal fittings.

-

What is Feeney CableRail made of?

All CableRail cables and fittings are made from high quality 316-grade stainless steel (also referred to as “marine grade”). This high-quality stainless steel offers beauty, superior weather durability, high strength and low maintenance characteristics that far exceed other traditional railing infill materials.

-

What will I need to maintain Feeney CableRail cables?

CableRail cables and fittings are made from high quality 316-grade stainless steel for weather-tough durability and very low maintenance. However, while rare, corrosion or staining may sometimes occur on stainless steel due to airborne contaminants, humidity, and other factors, especially in coastal environments. Periodic maintenance is recommended. Wipe the cables with soap and warm water and use either a rag or non-abrasive synthetic pad to keep them clean and free of salt or other contaminates. We also recommend our Stainless Steel Cleaner & Protectant Kit (#5064-PKG) with Feeney SteelProtect™ and SteelRenewal™. The SteelProtect™ product provides a protective layer that can help maintain the performance and luster of the cables and fittings. If any staining does occur, biodegradable SteelRenewal™ cleaning gel effectively removes staining and other contaminants without scrubbing. Simply apply, allow it to sit, and then rinse it off. Be sure to also check the cables periodically for proper…

-

Can you pass the Cable Lacing Needle through the Quick-Connect® Inset fitting?

No! The diameter of the Cable Lacing Needle is too large and will become wedged in the Quick-Connect® Inset fitting, rendering the fitting useless. Be sure to remove the Cable Lacing Needle and cleanly trim the end of the cable before inserting the bare cable into any Quick-Connect® style fitting.

-

What’s the longest cable run I can have?

When using our standard CableRail Kits, we recommend that straight runs of cable (no corners or bends) should not exceed 70 feet. Runs with corner bends (using double corner posts) should not exceed 40 feet and should not have more than two corners per run. Maximum run lengths may be less if using CableRail Conceal Kits or other Quick-Connect® or swage-type fittings. Give us a call to confirm the maximum run lengths for your specific project.