Build Them Right

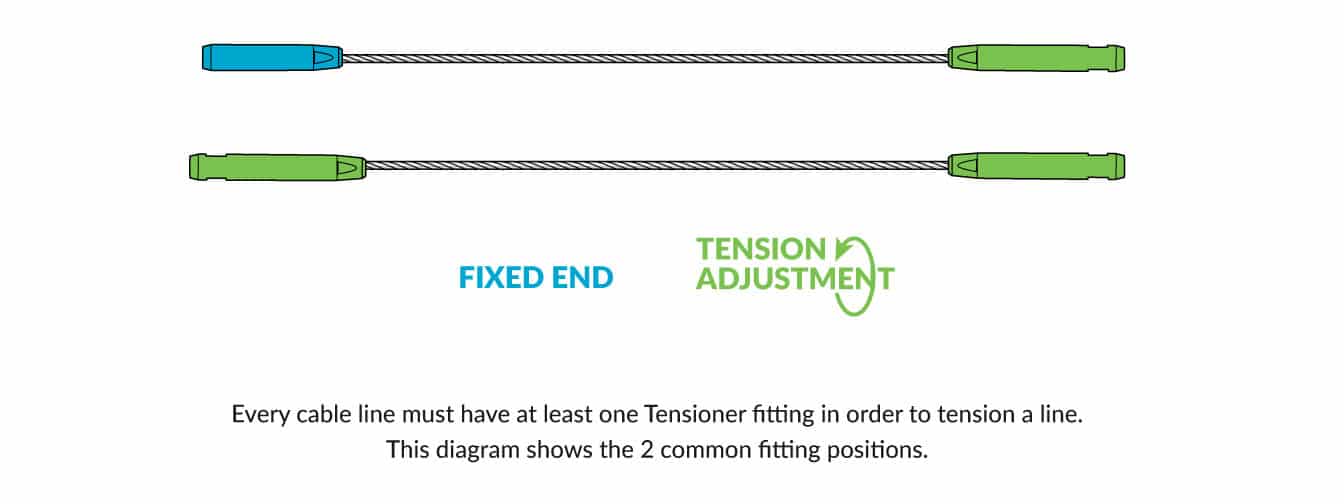

Using our Quick-Connect® style fittings with automatic-locking jaws and our bulk cable, you can build your assemblies in the field. The cable end is simply inserted into the fitting and the spring-loaded one-way jaws grab and lock on. If necessary, a reusable release tool can be used to disengage the cable and remove or readjust the fitting. Each assembly must have at least one Tension Adjustment fitting.

Bulk Cable

All fittings and cables are manufactured from high-quality 316-grade stainless steel for weather-tough durability, ultra-low maintenance, and lasting beauty.

Bulk Cable – 1/8″ diameter 1×19 cable construction is available in various lengths for use with CableRail fittings.

Lengths:

| Length | Part # |

| 100-ft | #5100 |

| 250-ft | #5250 |

| 500-ft | #5500 |

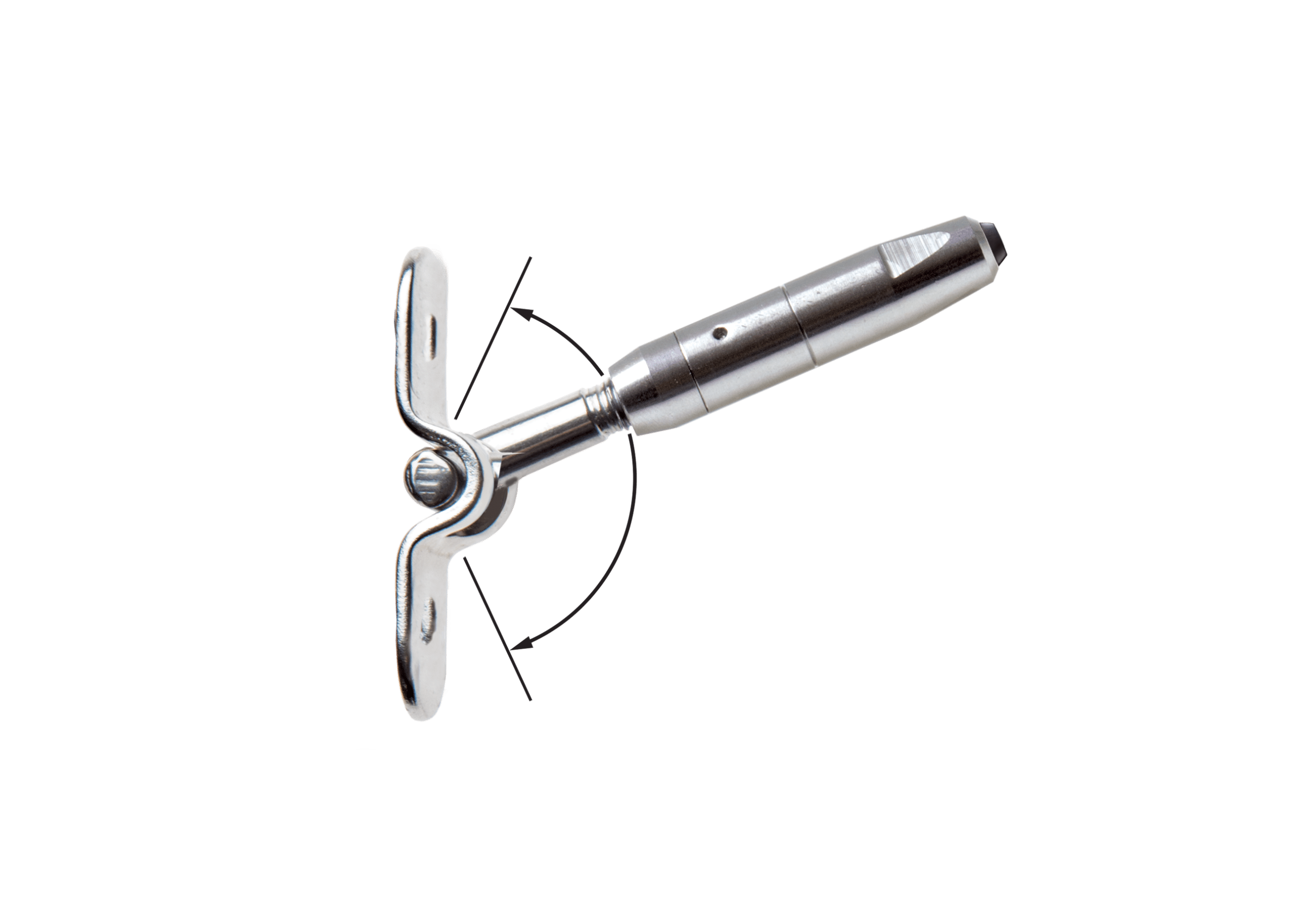

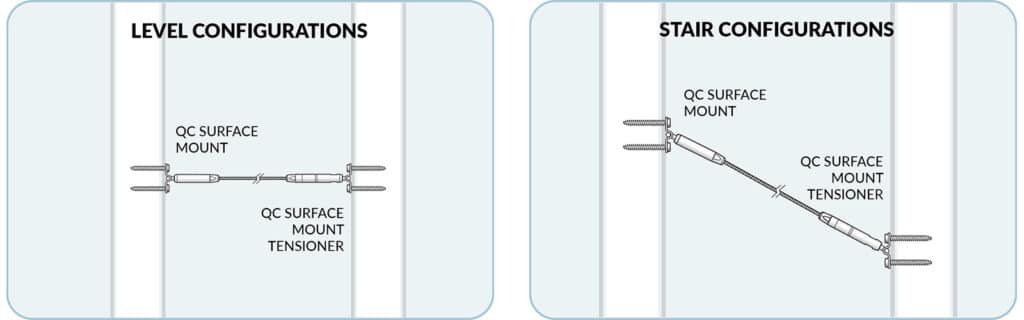

Quick-Connect® Surface Mount

9903DL-PKG

Fixed end fitting that attaches to the face of a post or wall with the included screws or bolts. 130° pivot range allows for angled stair terminations. Includes 2″ lag screws for wood posts (1/2″ bolts for metal posts sold separately).

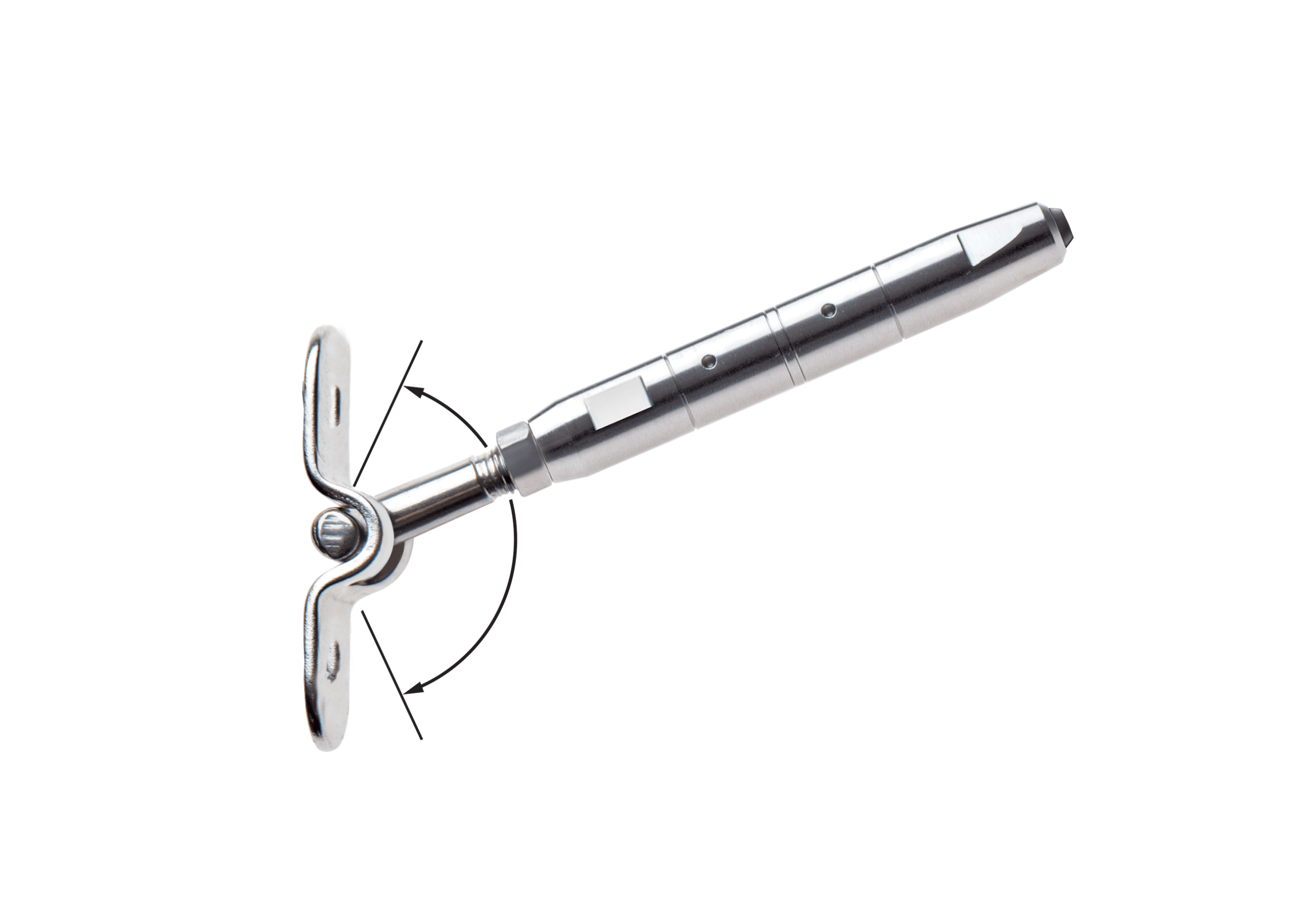

Quick-Connect®

Surface Mount Tensioner

9913DL-PKG

Surface Mount fitting with a special swiveling body that allows 3/4″ of take up for cable tensioning. Includes same hanger bolts as Surface Mount fitting.

Care and Maintenance

Feeney offers comprehensive care and maintenance documents categorized by material: one for stainless steel fittings and cables, and another for powder-coated aluminum products.

For best protection of CableRail, Feeney recommends using SteelRenewal™ and SteelProtect™, a stainless steel cleaner and protectant kit combo pack to help maintain your stainless steel surfaces.

FAQs

-

Can fittings and cable be purchased separately for fabricating assemblies in the field?

Yes. We offer a wide selection of cables and fittings, many of which include our Quick-Connect® automatic locking-jaw technology, all engineered for easy installation in the field. See our CableRail Fittings page for more information.

-

Can I cut the cables with a pair of wire cutters?

No. Wire cutters will crush the cable and cause you significant frustration during installation. You should use cable cutters that are designed to cleanly shear the cable (see our Cable Cutters #2972-PKG). An electric grinder with a cut-off disk is another option that works very well for trimming both the cable and the excess threads on the Threaded Terminal fittings.

-

Can you pass the Cable Lacing Needle through the Quick-Connect® Inset fitting?

No! The diameter of the Cable Lacing Needle is too large and will become wedged in the Quick-Connect® Inset fitting, rendering the fitting useless. Be sure to remove the Cable Lacing Needle and cleanly trim the end of the cable before inserting the bare cable into any Quick-Connect® style fitting.

-

How accurate do I need to be when measuring for my cable run lengths?

While it is always best to measure as accurately as possible, CableRail Kits allow for quite a bit of flexibility because they are sold in prefabricated, pre-cut lengths designed to be trimmed to exact length in the field. We recommend that you measure from outside-face to outside-face of the end posts (the posts you will attach the fittings to), and then add one foot to that length. You can then select a CableRail Kit that is at least as long as the augmented dimension. If you’re not sure, just give us a call at 1-800-888-2418.

-

How far apart can I space the cables?

The International Building Code states that a 4-inch sphere cannot pass through any opening in your railing and since cable is non-rigid, the flex of the cable must be taken into account. We recommend spacing the cables no more than 3 inches apart to allow for possible cable deflection and to meet the intent of the code. Before starting a CableRail project, installers should always check with their local building department to see if there are any special local requirements for using and installing cable railings.

-

How far apart can I space my posts?

We recommend having a post or vertical member (intermediate picket) at least every 3 feet. With the posts/verticals spaced 3 feet apart and the cables spaced 3 inches apart, you should be able to tension the cables so that they won’t open past the 4-inch sphere code requirement when a reasonable force is applied.